LYV AUTO – Steering Rack & Steering Pump Manufacturer

LYV AUTO has dedicated to manufacturing steering racks and steering pumps for the global automotive aftermarket since 2018. Our production facility spans over 8,000 sqm and operates with 120 workers, 5 workshops, and 12 production lines, with annual output of around 50,000 units.

All steering racks and pinions are produced under a strict 6S SAP management system to ensure stable and consistent quality. Every steering rack and power steering pump undergoes 100% inspection before package. To further guarantee reliability, we provide a 1-year warranty, and our standard after-sale service includes replacement of any confirmed defective product.

Beyond steering system, LYV AUTO also has continuously expanding product lines to automatic transmissions, cylinder heads, crankshafts, camshafts, bearing hub, ignition coil, brake pads and engine parts, meeting the needs of importers, distributors and professional repair shops around the world.

We actively participate in major exhibitions such as MIMS Moscow (see picture below), AAPEX, and Automechanika, and have built long-term partnerships across Central America, Latin America, Russia and CIS customers.

Here we introduce how LYV AUTO manufactures steering racks

This machine is performing precision finishing on a rack bar, ensuring smooth surface quality, correct tooth alignment, and stable performance for steering system applications. LYV AUTO uses advanced CNC equipment, polishing machine and strict process control to keep machining tolerances consistent for both aftermarket and OEM customers. The polished rack bars are inspected for straightness, hardness, and dimensional accuracy before entering the next production stage.

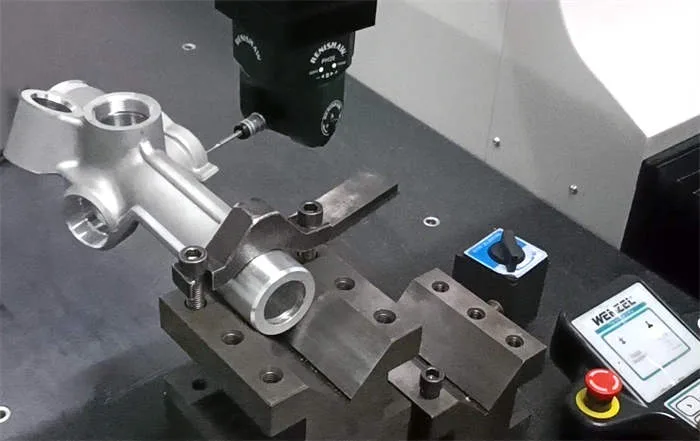

And below picture we use coordinate measuring machine to measure ensure each steering rack was well-precision includes dimensional accuracy, positioning accuracy, geometric accuracy, and contour accuracy.

These steering rack housings are CNC-machined with high precision and consistent dimensional accuracy to meet the standards of global aftermarket and OEM customers. LYV AUTO maintains strict quality control, including material verification, machining tolerance checks, and 100% quality inspection before proceeding to next processing. With stable production capacity and export experience to multiple countries, we supply reliable steering rack and power steering pump to distributors, wholesalers, and repair shops worldwide.

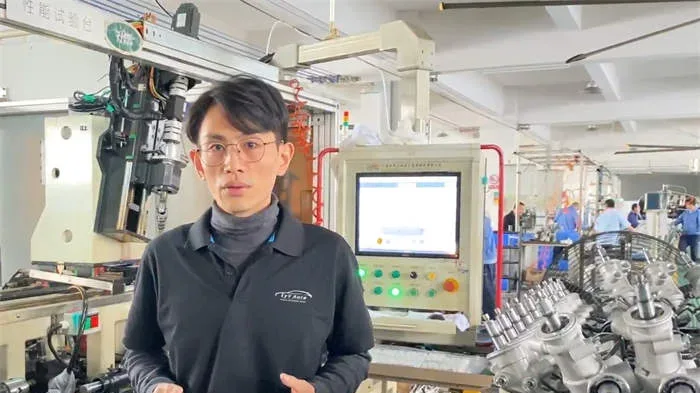

Each steering rack assembly undergoes 100% pressure testing and oil-seal airtightness testing to ensure durability and performance. As shown in the photo above, our sales team regularly visits the workshop to participate in and review the steering rack quality-control process once each assembly is completed.

The two pictures above show the finished Renault Logan I steering rack before packaging. You can clearly see the high-precision threading on the rack housing, the robust oil pipes, and the durable dust cover. We pay close attention to every machining step to deliver reliable, high-quality steering racks for our customers.

To enhance brand promotion and increase brand awareness, we offer customization of the steering rack and power steering pump with your exclusive branding. This includes:

– Designing your own color box

– Printing your own label on the box

– Printing your own code on the product

The image on the right shows a brown box with our LYV AUTO logo.

For more reliable and affordable steering racks, rack and pinion, steering pumps, and power steering pumps, LYV AUTO welcomes your inquiry and cooperation.

Together, we build a better world with LYV AUTO steering rack.